Good Quality LED Panel Light Manufacturer

OLALA is one of the top lighting Manufacturers & Suppliers in China.

More than 10 years of industry experience

LED Panel Light OEM & ODM Service

Small panel lights can be installed on the surface or in the dark, and the installation distance of each panel light can be adjusted according to the lighting requirements of the site. It is a better choice for large commercial residences and shopping malls.

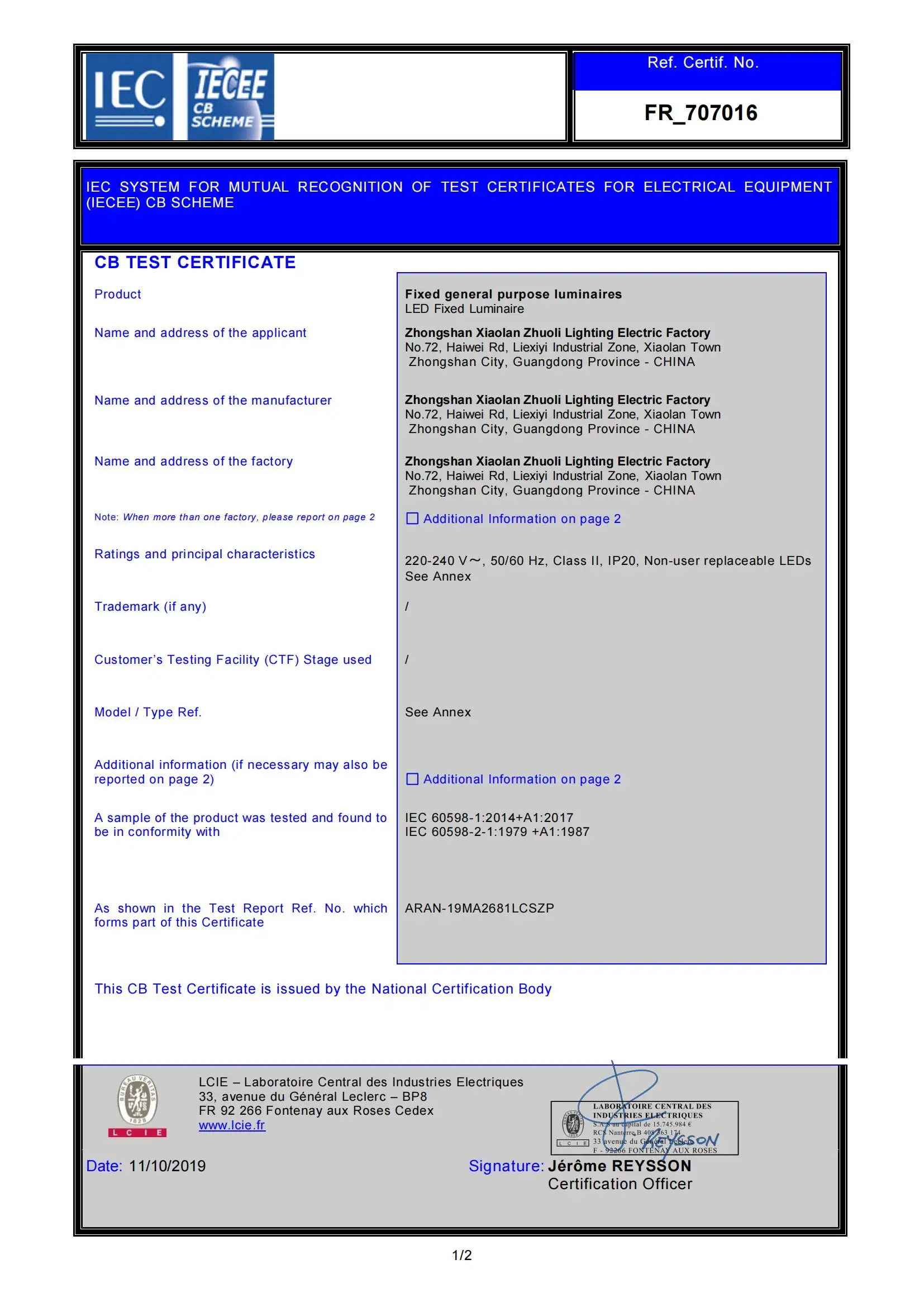

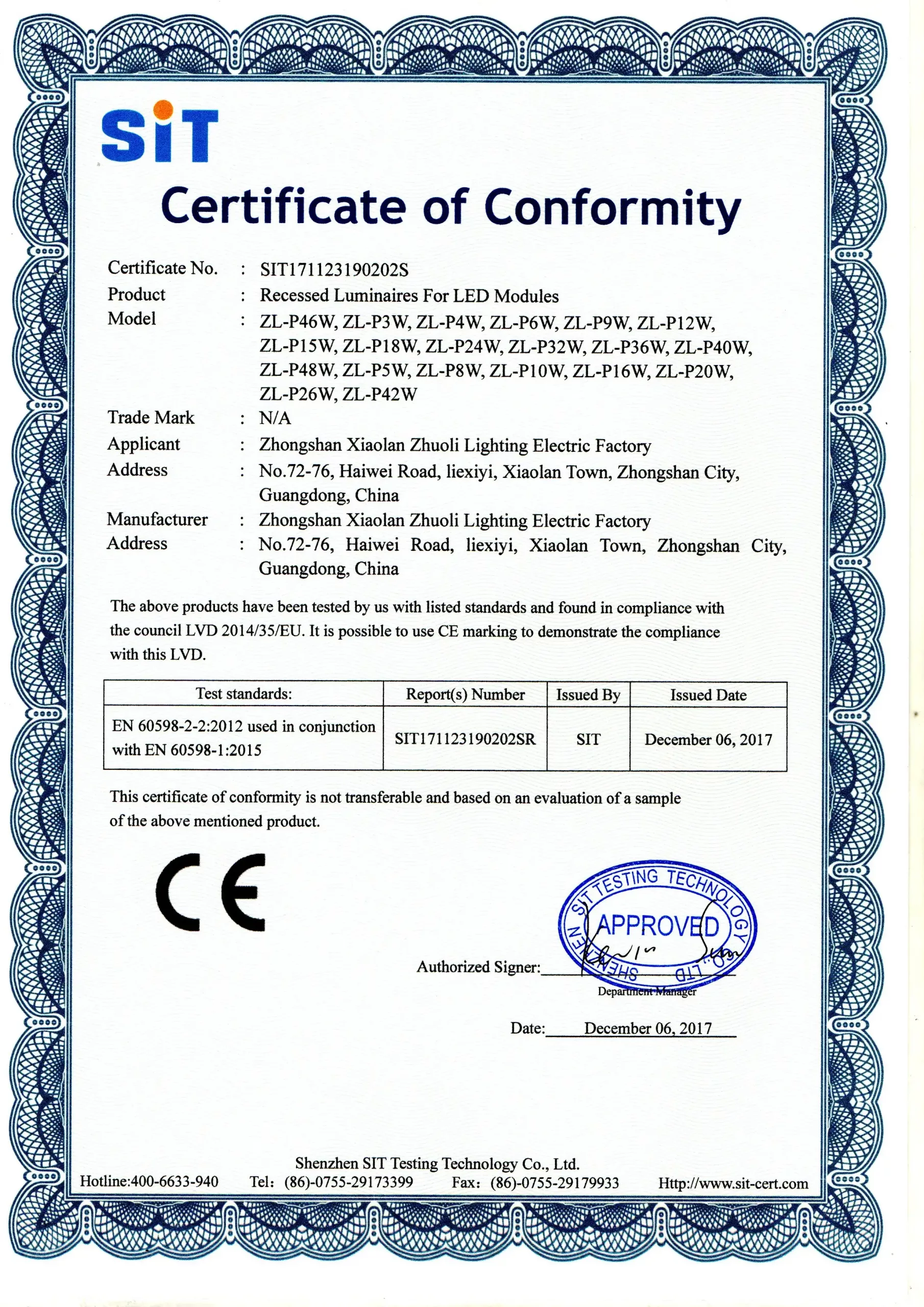

CB Certification

Our LED light panel can not only pass CB certification, but also have the quality to apply for CE and RoHS certification. To ensure long-term effective use in large warehouses and large buildings.

- Applicable to a variety of large spaces with low maintenance costs.

- COB or SMD light source can be selected.

- The heat dissipation performance is optimized to effectively protect the internal components of the lamp.

choose what you need

LED Panel Light Series

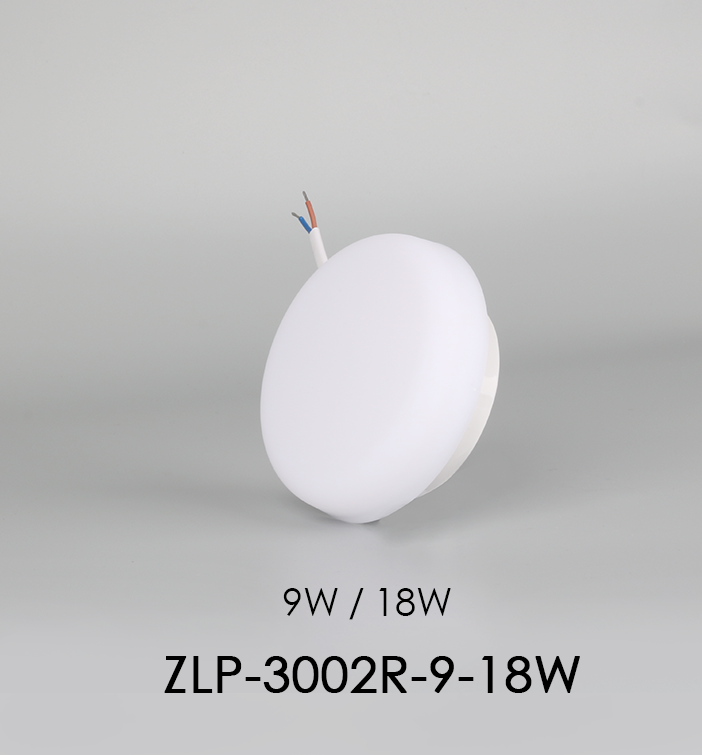

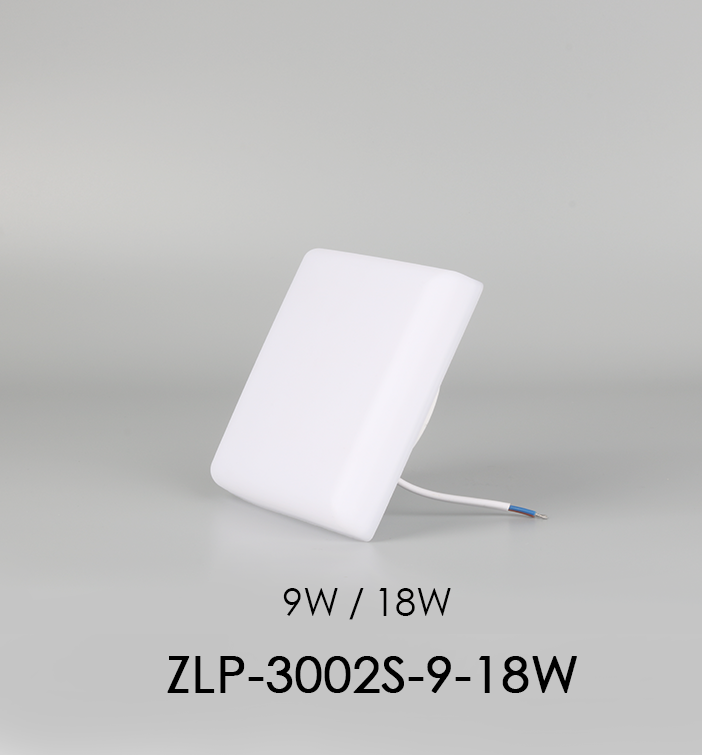

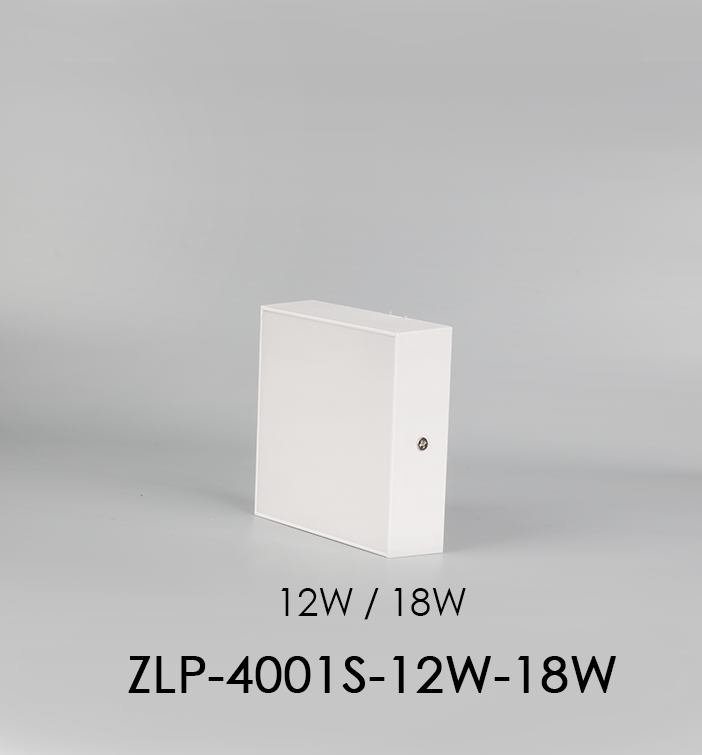

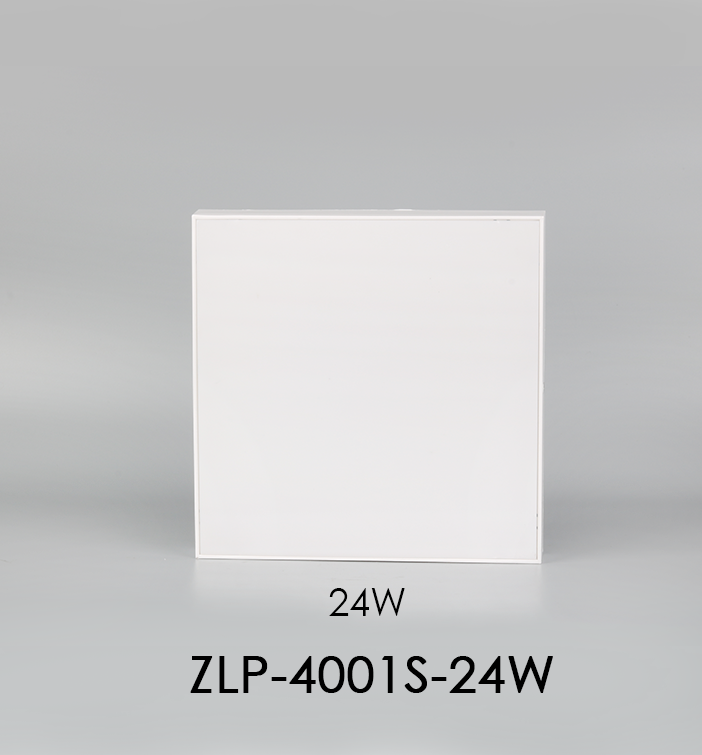

Regular wholesale panel lights are available in square and round shapes, and with thick and thin body. If you need to customize, we can also produce according to design drawings and light technical drawings.

Production Process Flow

The product quality of the panel light is one of the aspects that we are most concerned about.

Step 1

Apply glue

Step 2

Fixed drive

Step 3

Close the back cover

Step 4

Back cover screw

Step 5

Welding light board

Step 6

Install reflector

Step 7

Upper waterproof rubber ring

Step 8

Install the case

Knowledge

What is LED panel light?

LED panel light is a high-end indoor lighting fixture. Its outer frame is made of aluminum alloy by anodizing. The light source is LED. beautiful feeling.

The LED panel light has a unique design. The light passes through the light guide plate with high transmittance to form a uniform plane luminous effect. The illumination uniformity is good, the light is soft, comfortable and bright, which can effectively relieve eye fatigue. The LED panel light is also radiation-proof and will not irritate the skin of pregnant women, the elderly, and children.

Application

Application scope of LED panel light

LED panel lights are widely used, and there is a trend to replace grille lights; LED panel lights are mainly used in:

(1) Ceiling (replacing the original grille lights);

(2) Walls (not only for lighting purposes, but also for artistic expression);

(3) Installation body (pursuing the combination of practicality and art, convenient and simple installation);

(4) Others (can also be used in other places, such as train boxes or large mobile cars, counters, etc.);

Component

Component of panel light

(1) Panel light aluminum frame:

It is the main channel for heat dissipation of LEDs. The appearance is simple and elegant. ZY0907 can be used. The cost of die stamping is low, and the processing cost is also low; the IP level of the die-cast aluminum frame can be higher, the surface texture is good, and the overall appearance is beautiful, but the cost of the mold is invested in the early stage. higher.

(2) led light source:

Usually LED lamp beads use 2835, and some people use 3014 and 5050. 3014 and 5050 are low in cost, and the light efficiency is slightly worse. The key is that the design of their light guide points is difficult. 2835 has high light efficiency and good versatility.

(3) LED light guide plate:

The side LED light is refracted through the dots so that the light is evenly exported from the front, and the light guide plate is the key point of the quality control of the LED panel light. If the dot design is not good, the overall light effect seen will be very poor. Generally, there will be a bright middle and dark sides on both sides, or there will be a bright light band at the incoming light, or a local dark area may be visible, or there may be inconsistent brightness at different angles. To improve the light efficiency of the light guide plate mainly depends on the design of the dots, followed by the quality of the plate, but there is no need to superstitious the first-line famous brand plate, the light transmittance between qualified plates is usually almost the same. The general small LED lamp factory directly buys the public light guide plate and uses it, so there is no need to re-proof the design. The public version used by many manufacturers is usually of qualified quality.

(4) LED diffuser:

The light of the light guide plate is evenly exported, and it can also play the role of blurring the dots. The diffuser plate generally uses acrylic 2.0 sheet or PC material. The PS material is almost the same. The cost of acrylic is lower and the light transmittance is slightly higher than that of PC. Acrylic is brittle and has weak anti-aging performance. powerful. After the diffuser is installed, the dots cannot be seen, and the light transmittance should be about 90%. The light transmittance of acrylic is 92%, PC is 88%, and PS is about 80%. You can choose the material of the diffuser according to your needs. Most manufacturers use acrylic materials.

(5) Reflective paper:

Reflect the residual light on the back of the light guide plate to improve the light efficiency, generally RW250.